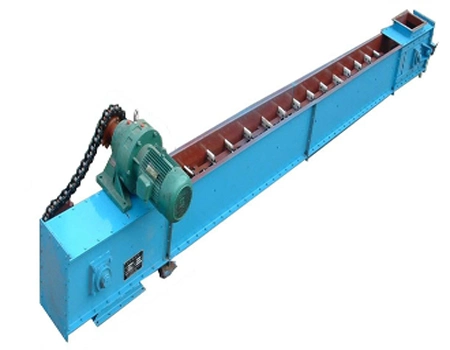

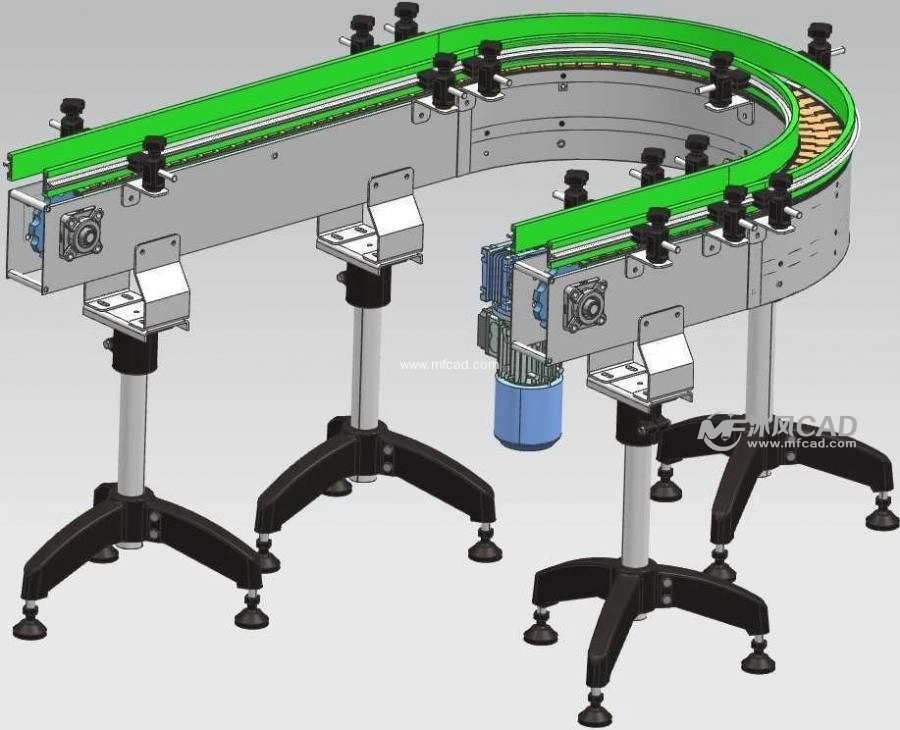

Wear Resistance UHMW Polyethylene Sheet offers great abrasion resistance, high impact strength, and excellent sliding properties, making it ideal for use in machine construction, plant construction, and conveyor technology. It's also ideal for use for fendering applications in ports, as a lining for highly exposed areas and as a material for the sports and skiing industry.

Ultra High Molecular Weight Polyethylene (UHMWPE) is a thermoplastic engineering plastic that combines the superior properties of all plastics. Mechanical properties are higher than high-density polyethylene, with outstanding wear resistance, impact resistance, low temperature wear resistance, stress crack resistance, high temperature creep resistance, low friction coefficient, self-lubricating, excellent chemical resistance Excellent performance such as fatigue resistance, noise damping, and nuclear radiation resistance. Can replace carbon steel, stainless steel, bronze and other materials used in textile, paper, food machinery, transportation, medical, coal, chemical and other sectors.

| SIZES |

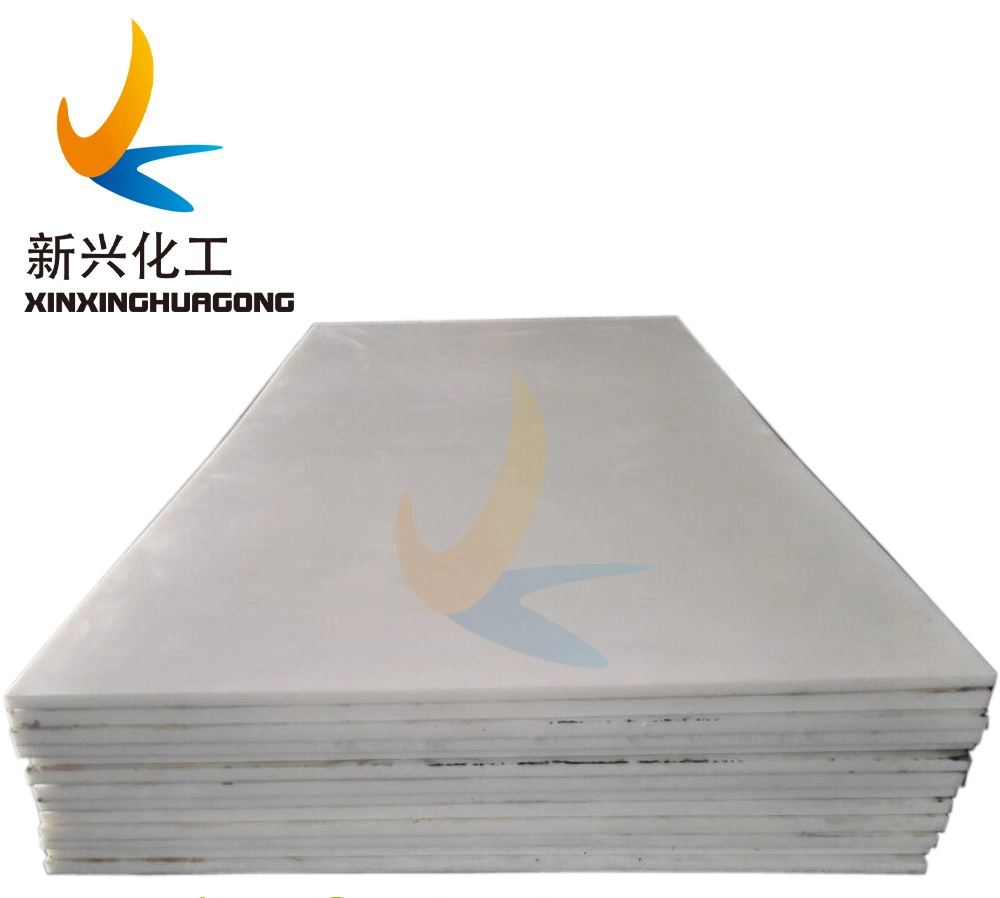

| 2000x1000x(6-300)mm | 3050x3050x(6-300)mm |

| 5040x1330x(6-300)mm | 4730x1230x(6-300)mm |

| 3050x1220x(6-300)mm | 6050x1820x(6-300)mm |

| 3030x1550x(6-300)mm | 4520x2000x(6-300)mm |

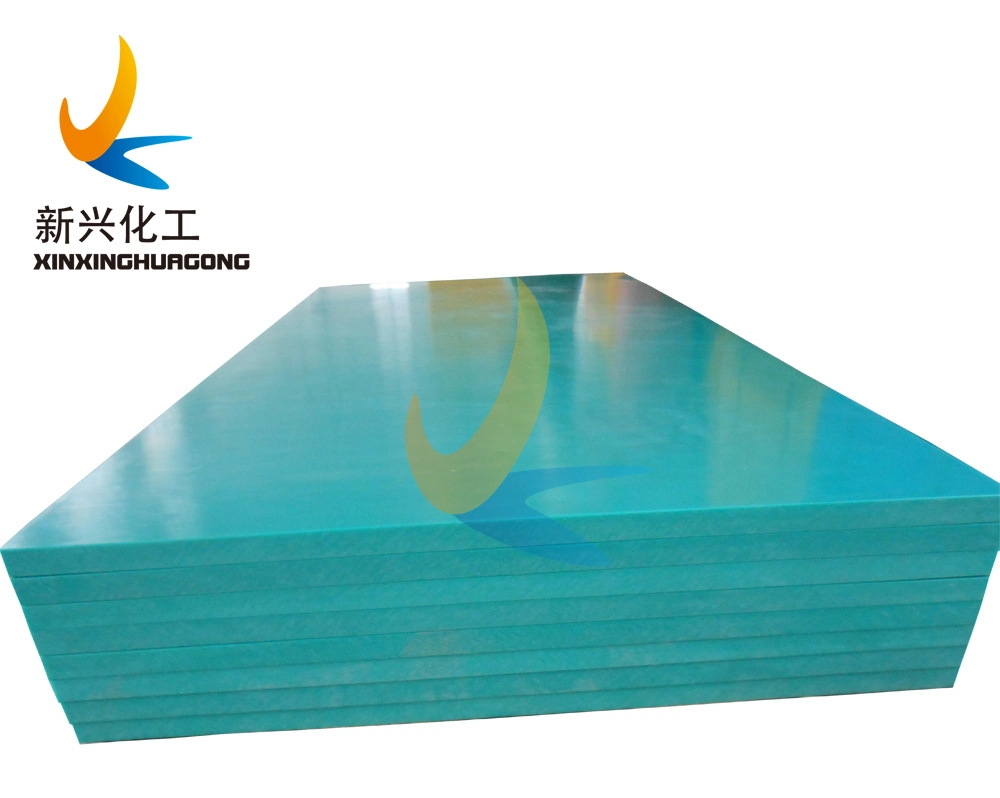

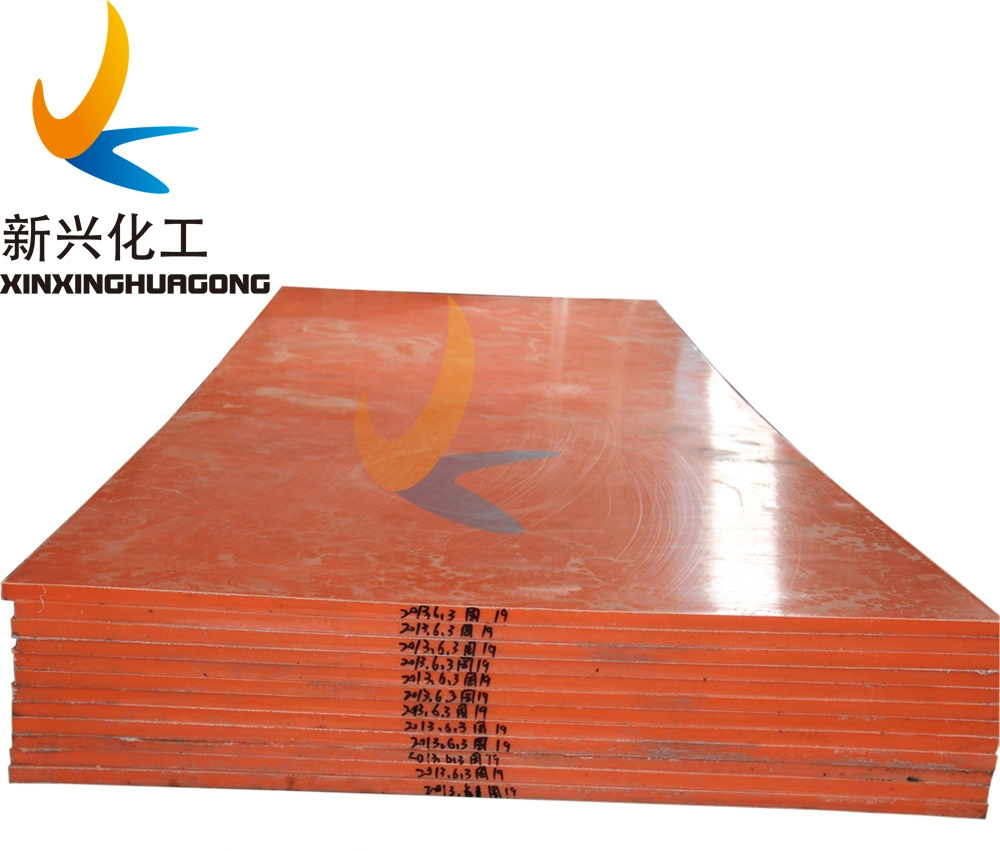

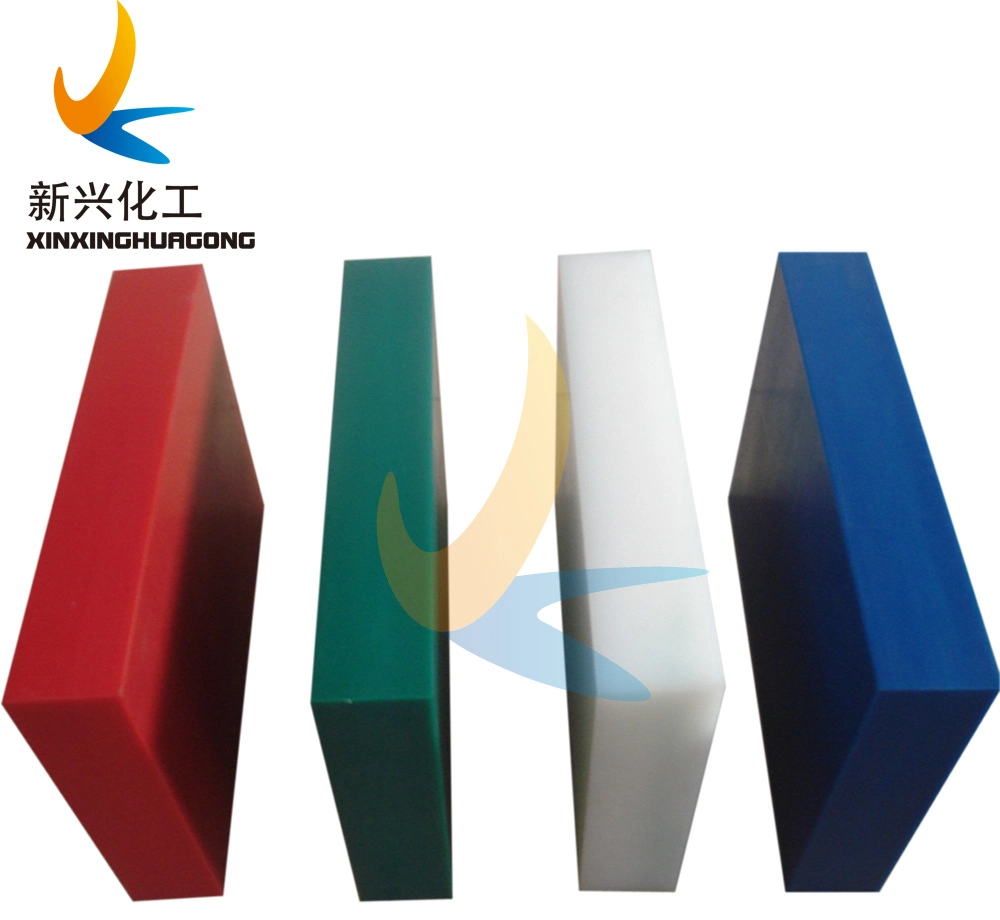

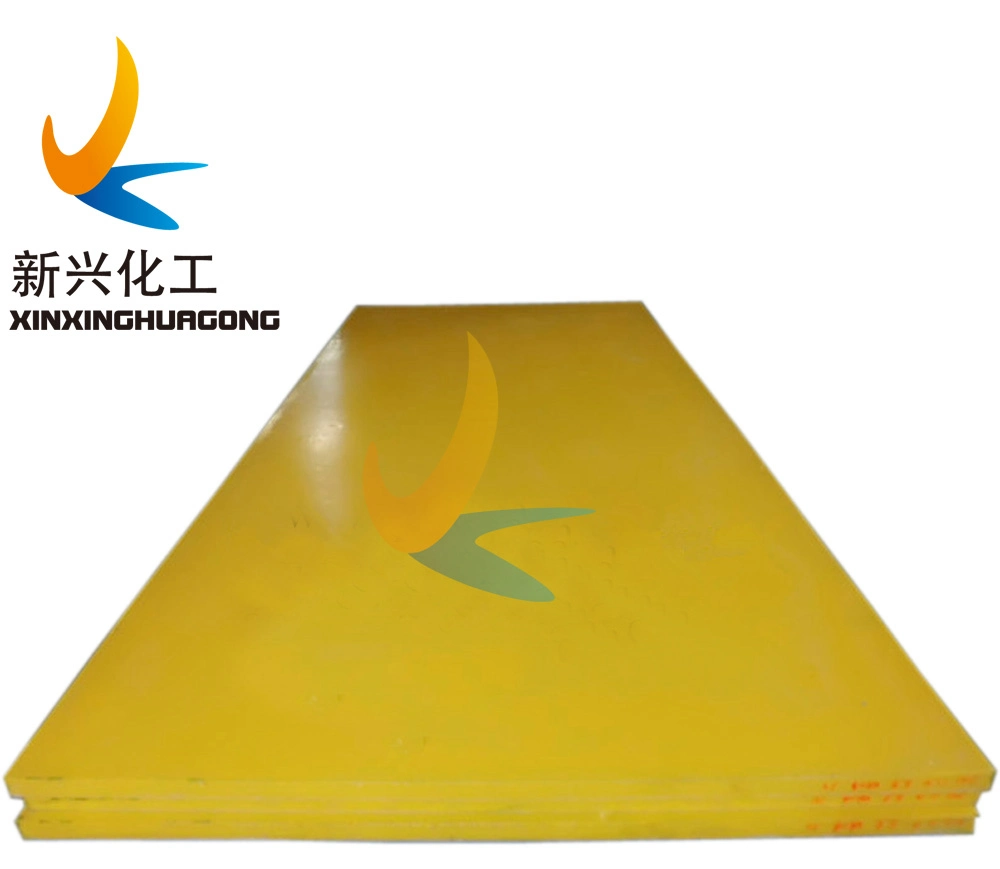

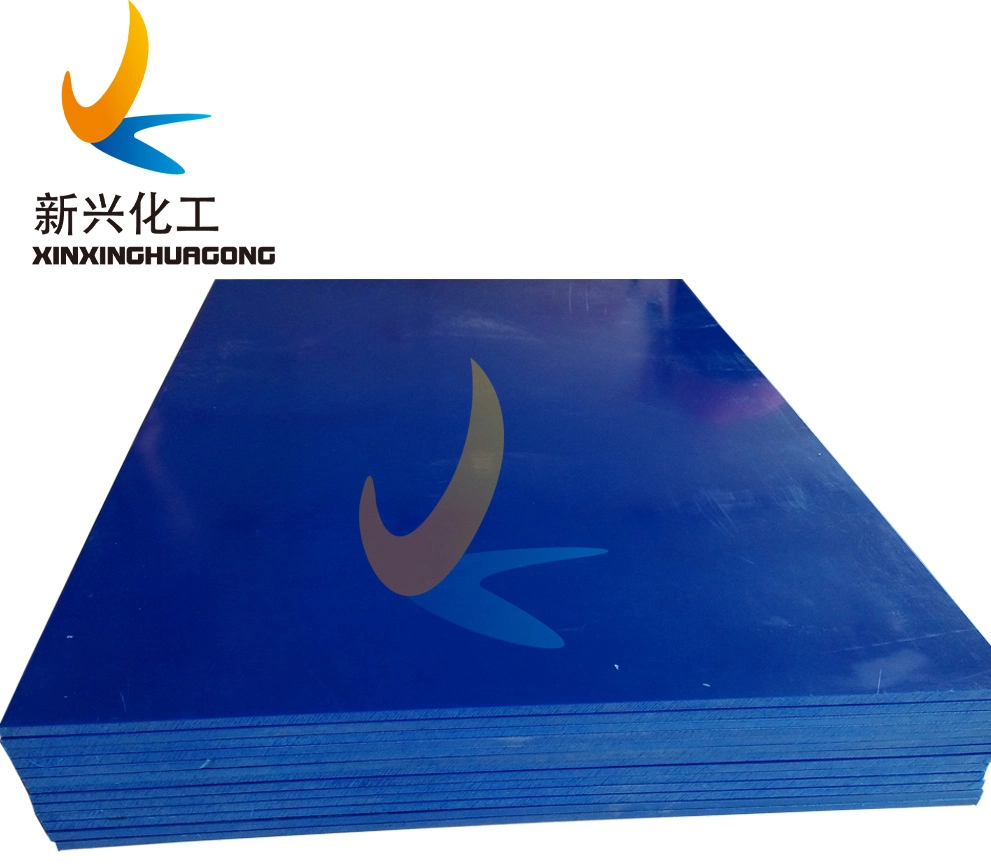

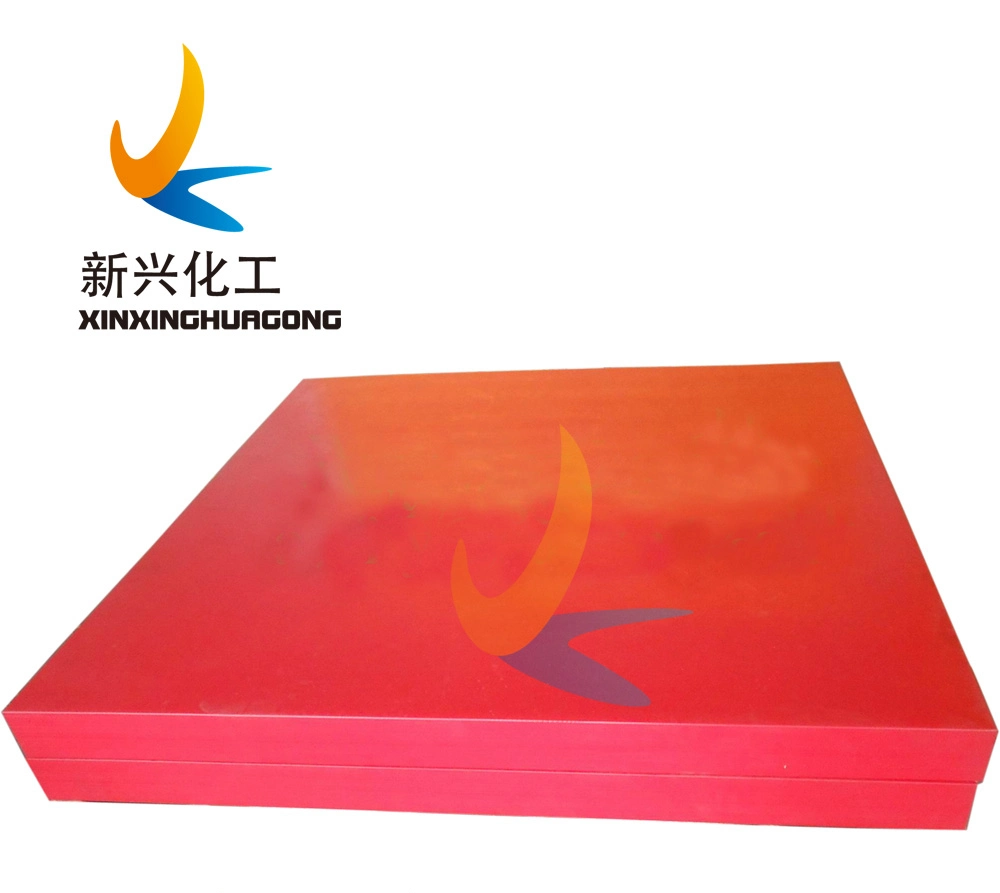

Color:

Black, Blue, Yellow, Green, White, Red, Orange, any other color will be available.

Wear Resistance UHMW Polyethylene Sheet, UV Resistant UHMWPE sheet

1.very flat on the surface

2.The thickness tolerance is +0.5 -0mm, some made according to your requirements.

3.The color is pure and any color can be made

4.We can give you an accurate size of UHMW-PE Sheet with advanced machine.

5.Different shaped UHMW-PE Sheets also can be made like bending sheet into desires design

6.According to different requirements with different application, special specifications can be customized, like anti-UV, fire-resistant,anti-static and with other characters.

7.we can also print logos on the sheets ,any design any language

The properties of UHMW-PE:

Property: | Test Method (Standard) | Ticona GUI4152 | Ticona GUI4150,4120 | Unit |

Molecular weight |

| 1.5million-4million | 1.5million-8million |

|

Density | ISO 1183-1:2012/DIN53479 | 0.92-0.98 | 0.93-0.98 | g/cm³ |

Compression strength | ISO 604:2002 | ≥30 | ≥32 | Mpa |

Tensile strength | ISO527-2:2012 | ≥20 | ≥22 | Mpa |

Elongation at break | ISO527-2:2012 | ≥280 | ≥300 | % |

Dynamic Friction coefficient | ASTM D 1894/GB10006-88 | ≤0.20 | ≤0.18 |

|

Notched impact strength (Charpy) | ISO179-1:2010/GB/T 1043.1-2008 | ≥100 | ≥100 | kJ/m2 |

Abrasion wear index | ES-X60210-2008 | ≤30 | ≤30 | mg |

Vicat softing point | ISO306:2004 | ≥80 | ≥80 | °C |

Hardness shore-D | ISO 868:2003 | 60-65 | 61-66 | D |

UHMW-PE Advantages & Key Features

--Highest abrasion resistance of any polymer, 6 times more wear resistant than steel

--Anti-Weather & Anti-Aging

--Self-lubricating, Very low coefficient of friction

--Excellent chemical & corrosion resistant

--superior impact resistant, Noise- absorption, Vibration-absorption

--Temperature range: -2600C ~ +800C; Very high resistance to cold,doesn't become fragile even under -1800C

--High tensile Strength

--Non-Toxic and smell

--UV resistance

--Flame Retardant; Relatively low in water absorption

--Excellent electrical properties

--Good performance in resisting environment stress crack, 200 times of ordinary PE

--No adhesion

--Light weight and easier to handle and fix

--Cost efficient; Resulting in low energy consumption

--Does not rot, split or crack; 100% recyclable

--Great liner material for industrial material handling applications

--Easy Reprocessed

Applications