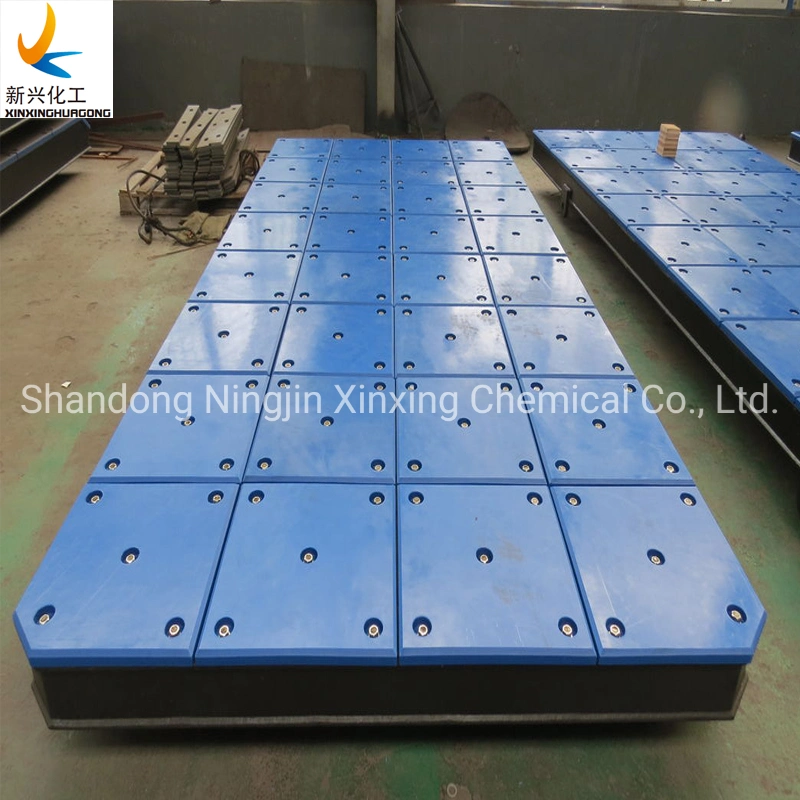

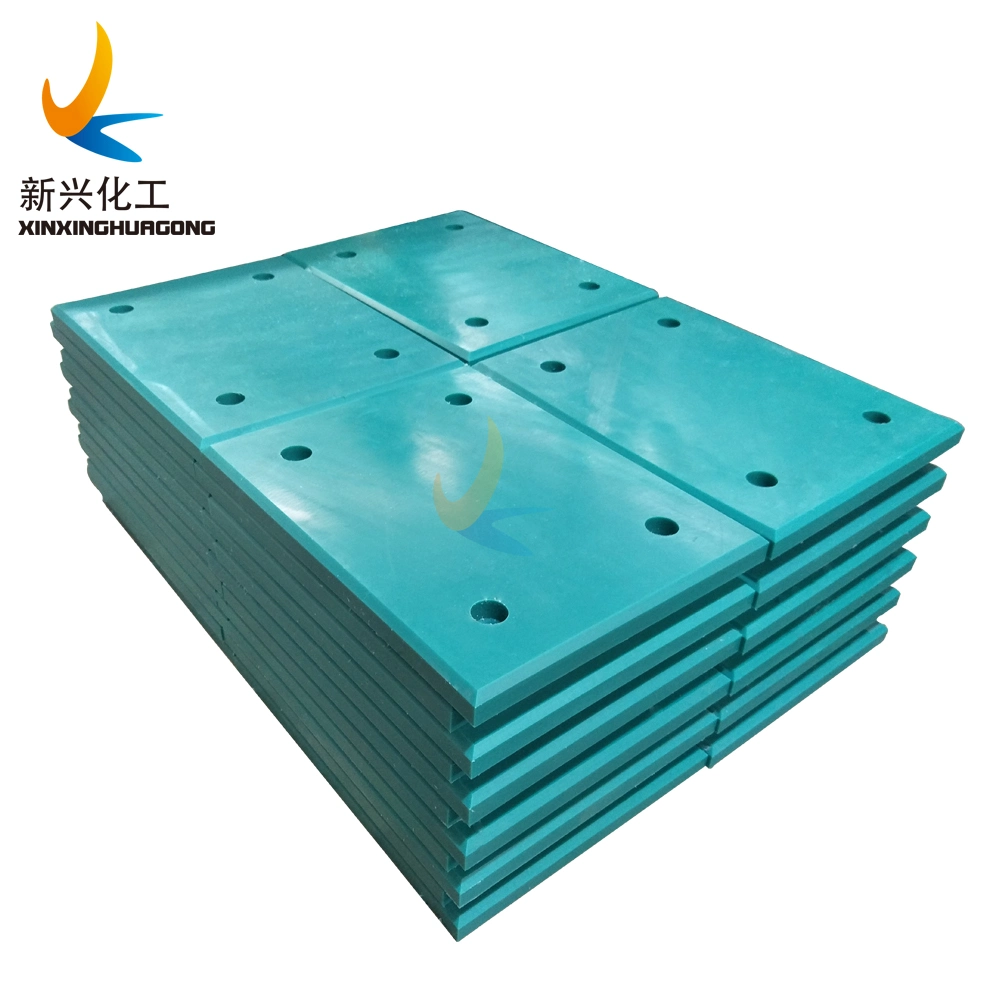

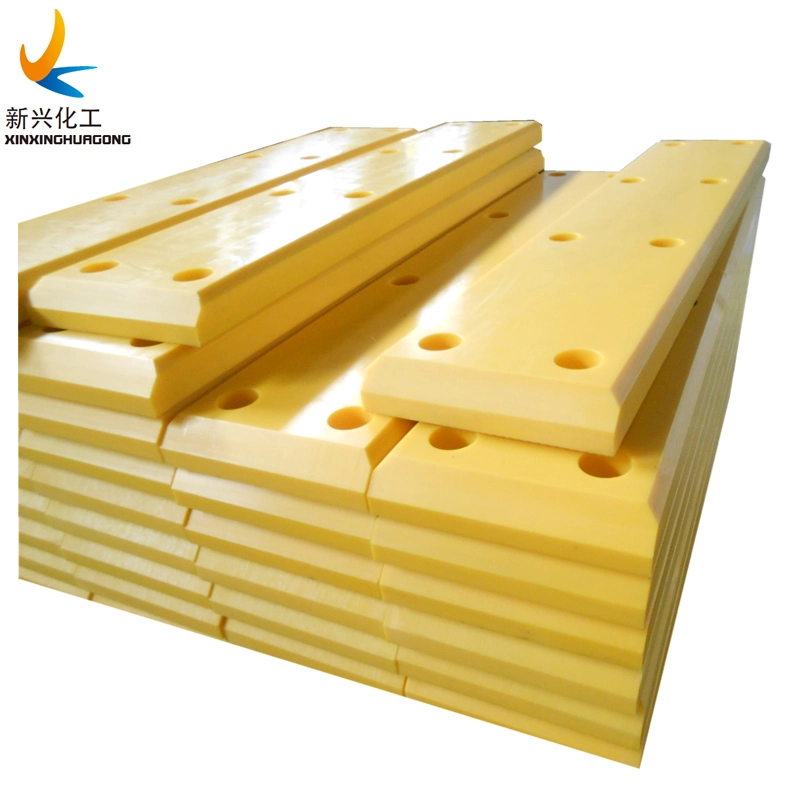

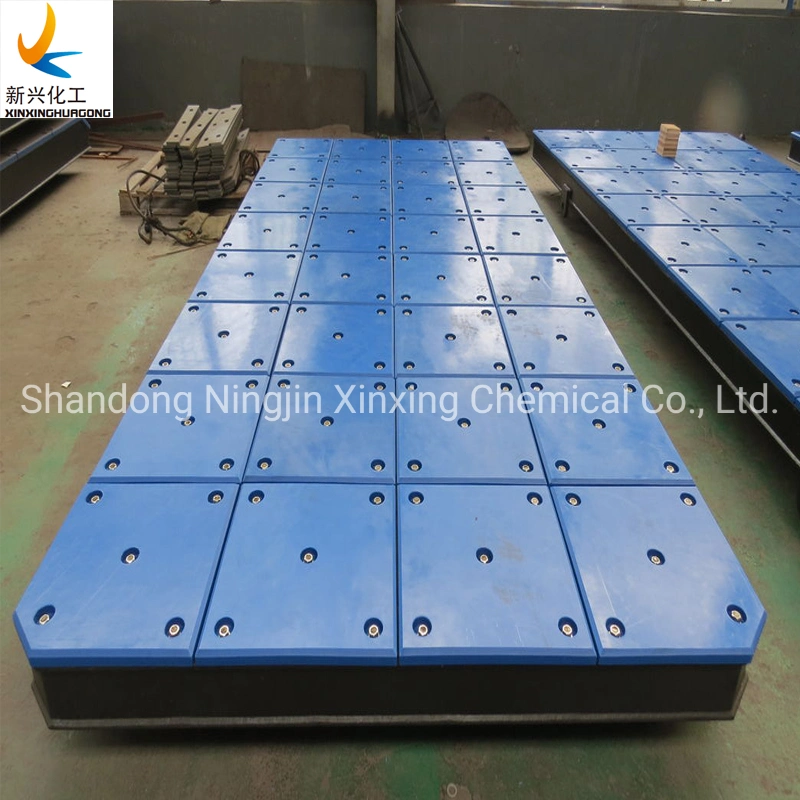

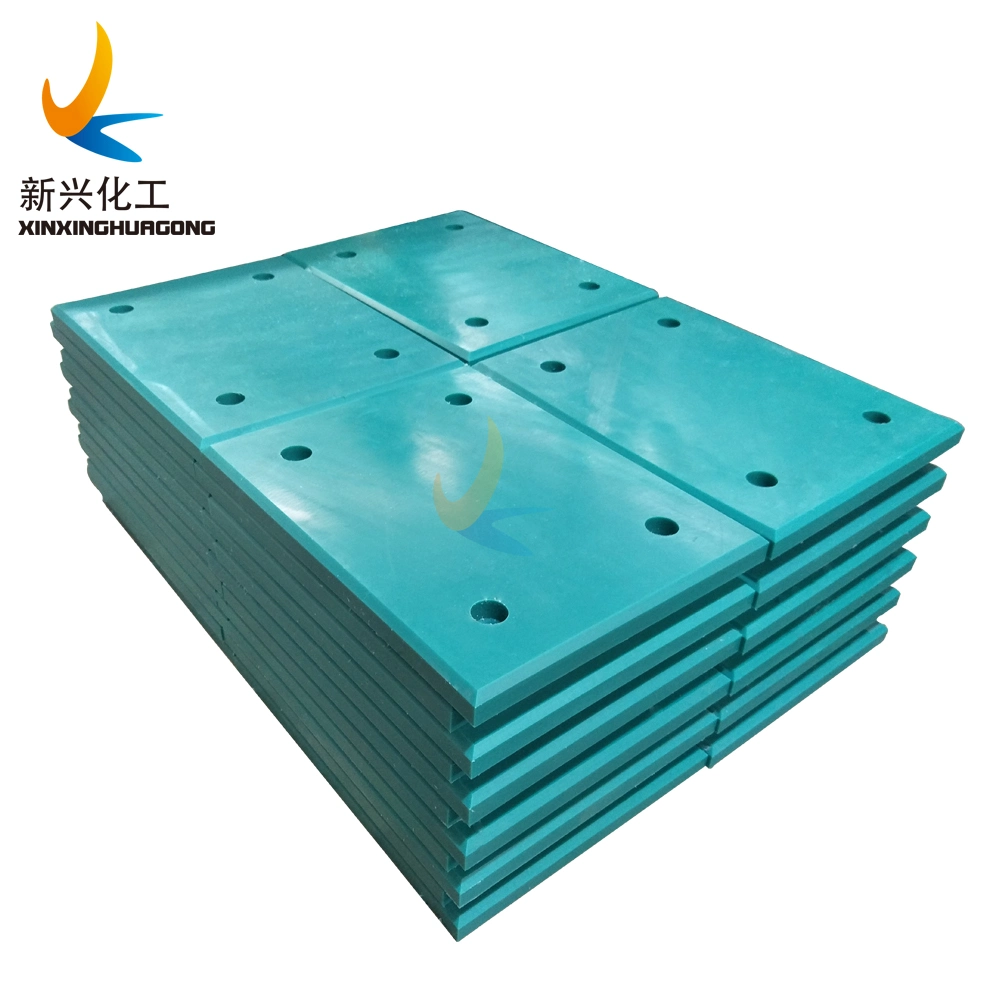

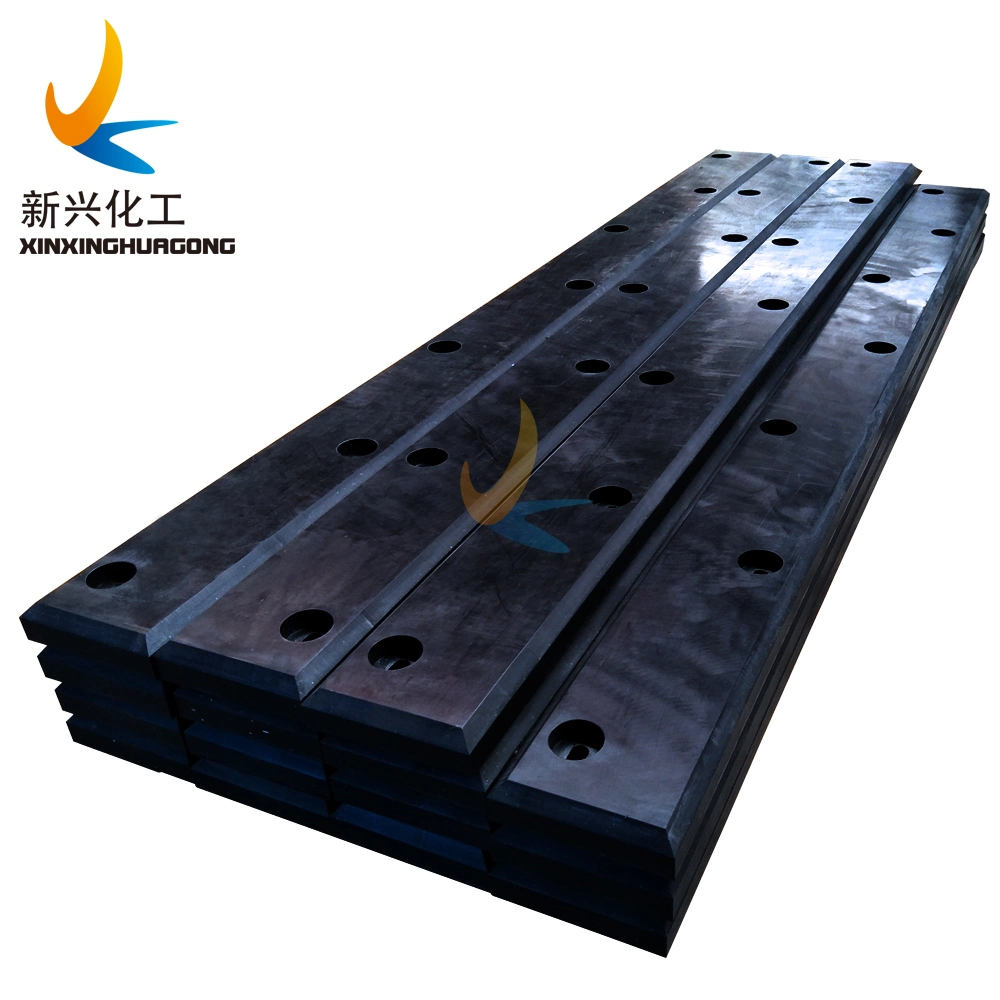

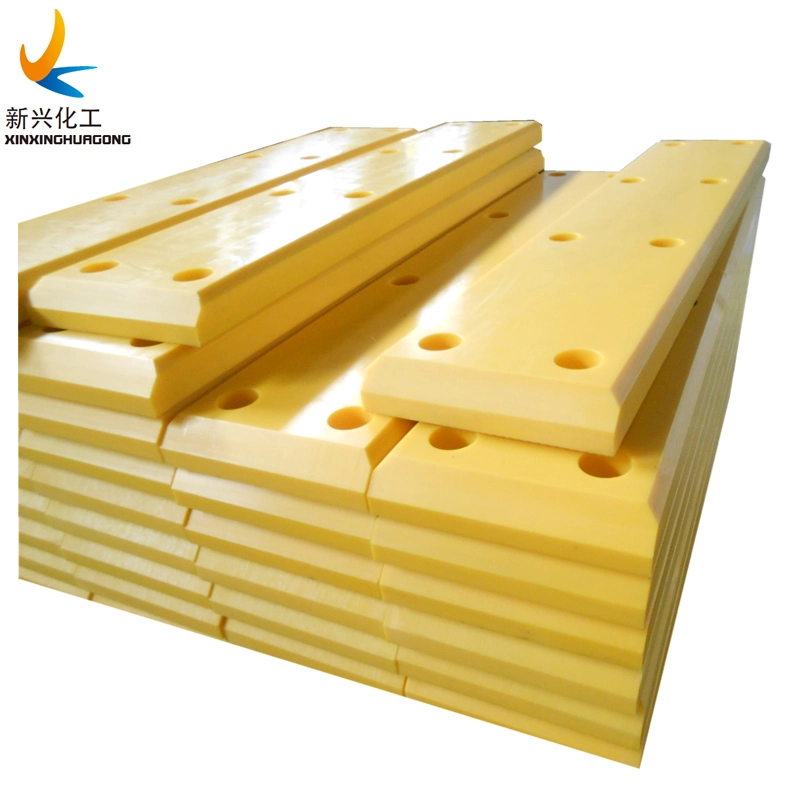

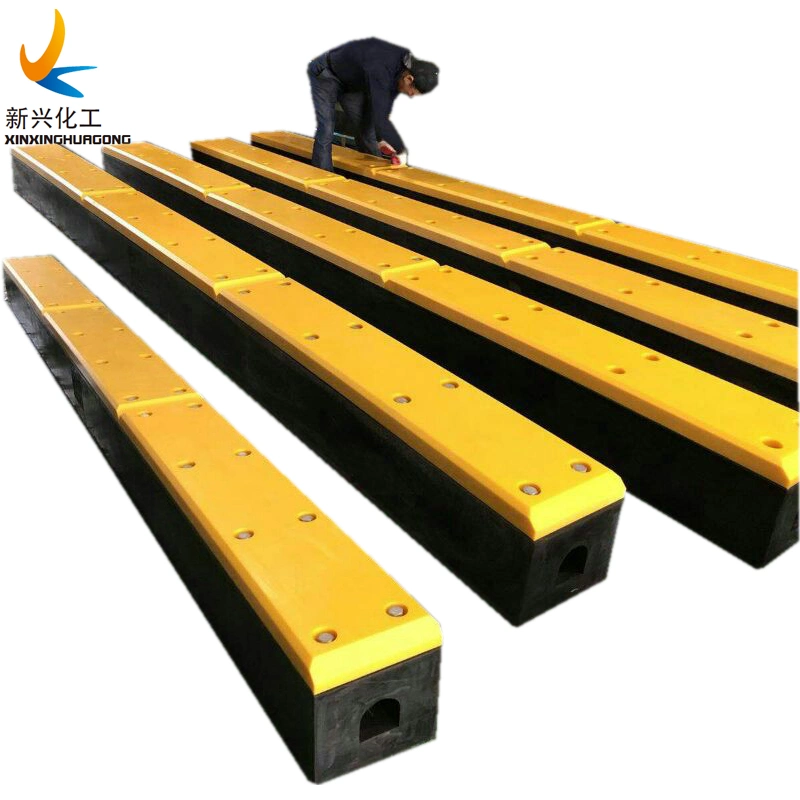

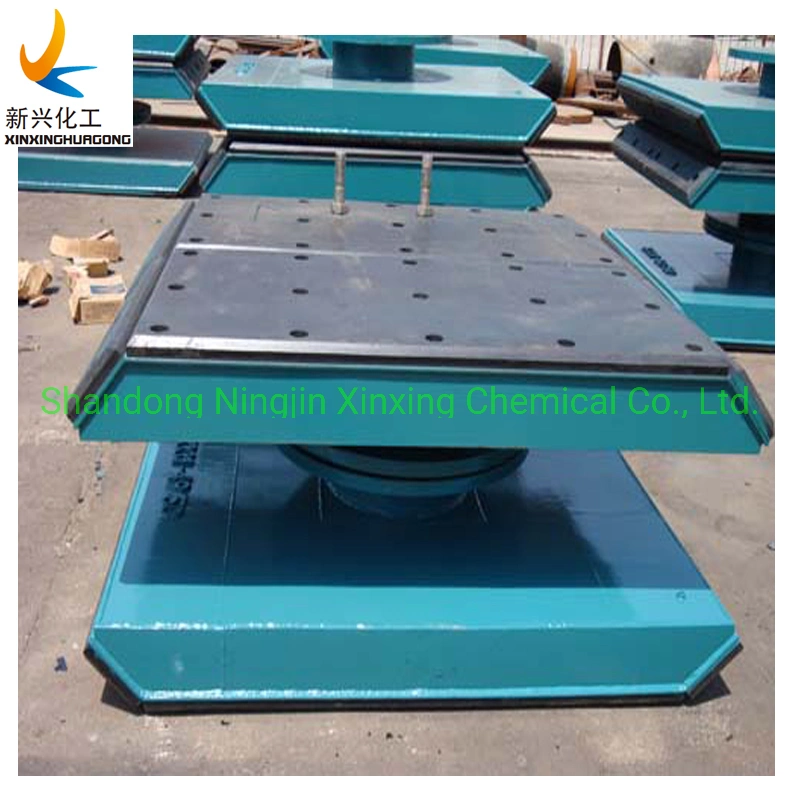

UHMWPE marine boat fender pads wharf fender facing panel

Fender panels distribute reaction forces to provide low hull pressures and cope with large tidal variations. They can also be designed to resist line loads from belted ships, or even point loads in special cases. Optional lead-in bevels reduce the snagging risk, whilst brackets (where required) provide highly secure connection points for chains. Closed box designs are used almost exclusively - all fully sealed, and pressure checked. Corrosion protection is provided by high durability C5M class paint systems to ISO9001, and additional corrosion allowances can be designed where required.

FEATURES & OPTIONS

Closed box steel structure

Internal structural members

Blind boss fender connections

Pressure tested for water tightness

C5M modified epoxy paint*

PANEL SPECIFICATIONS AND DESIGNS SHOULD CONSIDER:

APPLICATIONS

Related products:

FEATURES & OPTIONS

Closed box steel structure

Internal structural members

Blind boss fender connections

Pressure tested for water tightness

C5M modified epoxy paint*

PANEL SPECIFICATIONS AND DESIGNS SHOULD CONSIDER:

- Hull pressures and tidal range

- Lead-in bevels and chamfers

- Bending moment and shear

- Local buckling

- Limit state load factors

- Steel grade

- Permissible stresses

- Weld sizes and types

- Pressure test method

- Rubber fender connections

- UHMW-PE attachment

- Chain connections

- Lifting points

- Paint systems

- Corrosion allowance

- Maintenance and service life

- wear resistance, strong anti sliding friction.

- impact toughness.

- Strong corrosion resistance.

- Self-lubrication.

- Non-toxic. UHMW is non-toxic and harmless

- Low temperature resistance and anti aging.

- Surface non adhesion, non fouling.

- Excellent crack resistance.

APPLICATIONS

- Fender panel (frame) face pads

- Rubbing strips

- V-fender shields

- Lock entrance and wall protection

- Bridge buttress protection

- Beltings on workboats

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Related products:

|  |