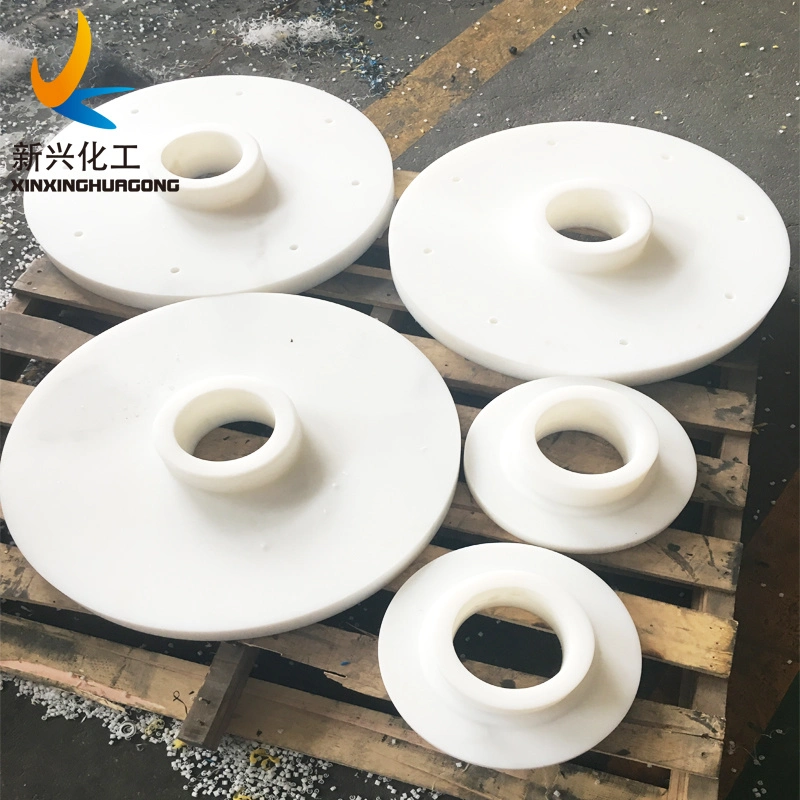

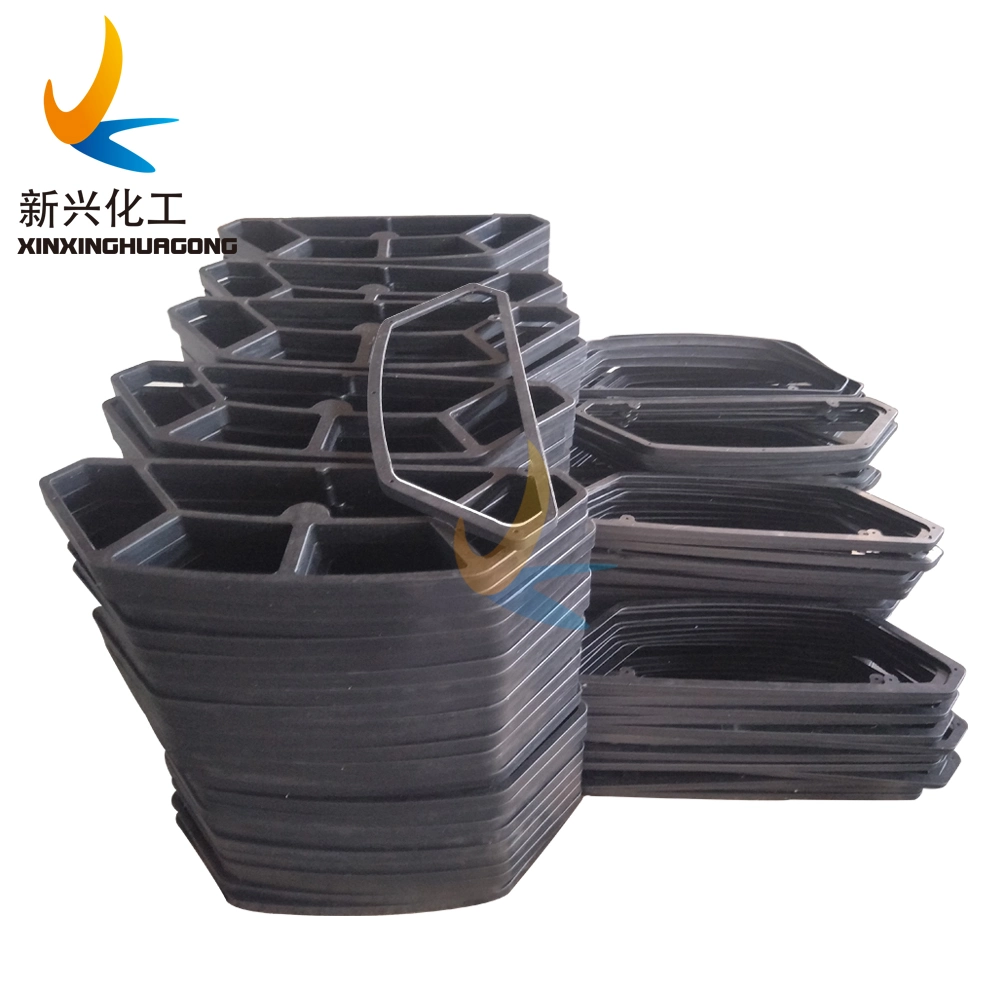

UHMWPE machined parts

XINXING can make custom UHMW Machined Parts to your specifications or drawings. We have a plastic machine shop; UHMW is one of the plastics we can use to make parts.

MATERIAL DESCRIPTION

UHMW stands for ultra high molecular weight polyethylene or UHMWPE.

Polyethylene materials are semi-crystalline materials with excellent chemical resistance, good fatigue and wear resistance, and a wide range of properties (due to differences in length of the polymer chain).

Polyethylene materials are easy to distinguish from other plastics because they float in water. Polyethylene materials provide good resistance to organic solvents, degreasing agents, and electrolytic attack.

They have a higher impact strength, but lower working temperatures and tensile strengths than polypropylene. They are light in weight, resistant to staining, and have low moisture absorption rates.

XINXING can make custom UHMW Machined Parts to your specifications or drawings. We have a plastic machine shop; UHMW is one of the plastics we can use to make parts.

MATERIAL DESCRIPTION

UHMW stands for ultra high molecular weight polyethylene or UHMWPE.

Polyethylene materials are semi-crystalline materials with excellent chemical resistance, good fatigue and wear resistance, and a wide range of properties (due to differences in length of the polymer chain).

Polyethylene materials are easy to distinguish from other plastics because they float in water. Polyethylene materials provide good resistance to organic solvents, degreasing agents, and electrolytic attack.

They have a higher impact strength, but lower working temperatures and tensile strengths than polypropylene. They are light in weight, resistant to staining, and have low moisture absorption rates.

Features of UHMWPE

1. UHMW exhibits virtually no water absorption

2. Non-Toxic

3. Low coefficient of friction

4. Corrosion resistant

5. Abrasion and impact resistant

6. Wear Resistant

7. Dielectric

8. Weatherproof

Application of UHMWPE Plastic irregular parts:

1 Paper Industry

2 Transportation

3 Material Handling

4 Consumer Products

5 Chemical Industry

6 Food Processing Industry

7 Waste Water Treatment

8 Mining & Metals Processing Industries

Parameter

| Items | Unit | Data | ASTM Test Method |

| Molecular Weight | billion | 3~9 | D2857 |

| Specific Gravity | g/cm^3 | 0.935~1.0 | D1505 |

| Tensile Strength | MPa | 40~45 | D638 |

| Elongation at break | % | 300~400 | D638 |

| Impact Strength | kJ/m^2 | ≥140 | D250 |

| Rockwell Hardness | kJ/m^3 | 40~60 | D747 |

| Abrasion Loss | mg/1000 times | 70 | D1175 |

| Distortion Temperature | ºC | 85 | D648 |

Advantages of UHMWPE irregular parts:

1.Abrasion highest plastic, seven times higher than carbon steel, four times higher than PTFE.

2.Self-lubricating performance

3.Impact strength, 2 times higher than that of polycarbonate, 5 times higher than ABS.

4.Nonstick surface of product compared with other materials is not easy to attach, strong anti-adhesion properties.

5.Corrosion resistance: at a certain temperature and humidity resistant to concentrated acid, alkalis, corrosive chemicals, high chemical stability.

Our advantage:

1.Nearly 30 years professional manufacturing experience with own factory.

2.Virgin 100% material produced. high quality with good surface and color make ensured.

3.Competitive price,in stock,Fast delivery, and Excellent service.

4.GBT/T 19001-2008;ISO 9001:2008 certification.

5.OEM available.special character is available:According to different requirements with different application,color,size,shape and special specifications can be customized,such as anti-UV,anti-static,and so on.

6.Strict quality control.

Main Products:

Ground protection mats, Marine fender facing pads, outrigger support mats, Synthetic ice rink system ( synthetic ice skating floor, and dasher boards), HDPE and UHMWPE boards, HDPE and UHMWPE machined parts...