Hot Selling, Self Lubricating UHMWPE Polyethylene Conveyor Wear Strips, Okulen UHMW-PE1000 Various Wear Strips

Brief Introduction

UHMWPE resin is an engineering thermoplastic composed of ethylene and butadiene monomer---under the action of catalyst. The viscosity average molecular weight of UHMWPE is more than 1.5 million --- 7 million, therefore, it is called "The Fantastic Plastic".

UHMWPE (Ultrahigh molecular weight polyethylene) is a thermoplastic engineering material with high molecular weight and excellent performance.

On the whole, it almost focused on the advantages of all kinds of plastic, which has incomparable wear resistance, impact resistance, self-lubrication, corrosion resistance, low temperature resistance, sanitary nontaxicity, extremely high smoothness and low water absorption.

In fact, there is no single polymer material has so many excellent properties like UHMWPE material.

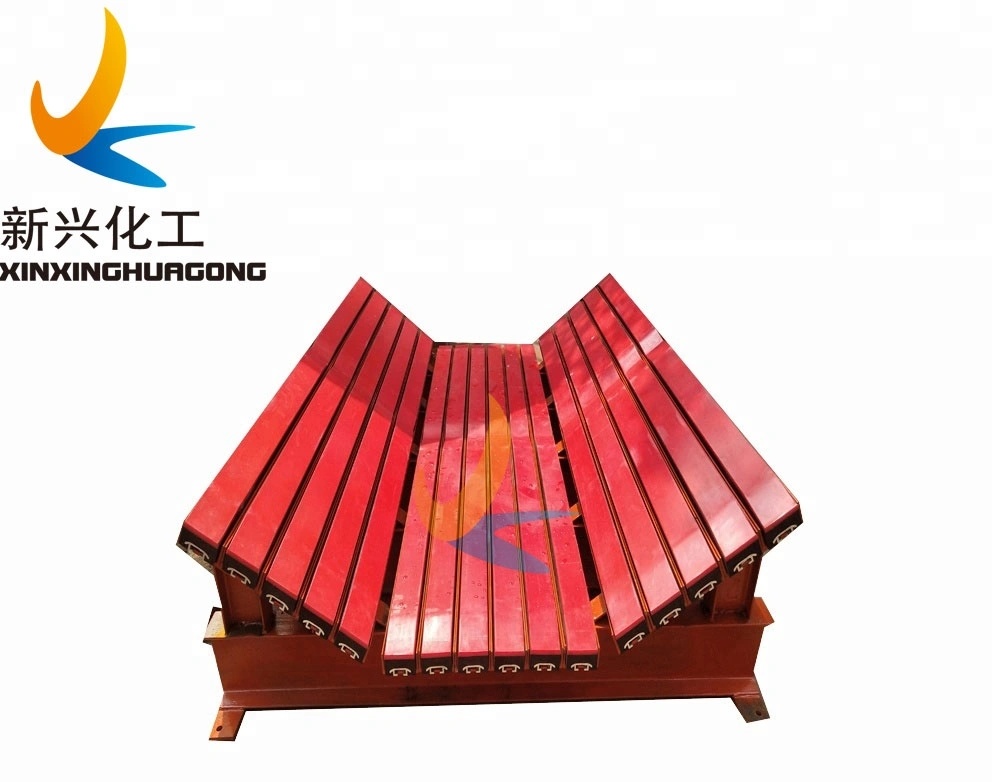

These wear strips are mounted on the tracks over which the chain travels. Special Antistatic grade of Ultra High Molecular Weight Polyethylene (UHMWPE) having antistatic property ensures its suitability for LPG installations, reducing chances of sparks / static current developed because of friction.

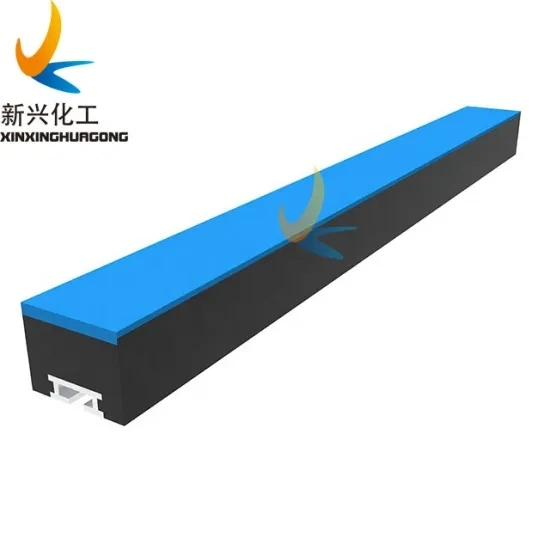

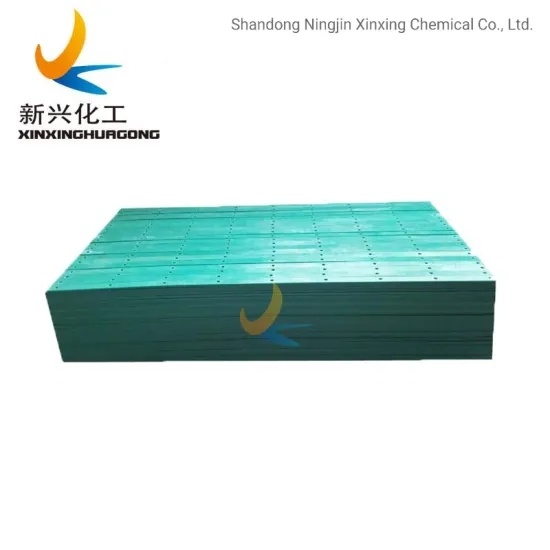

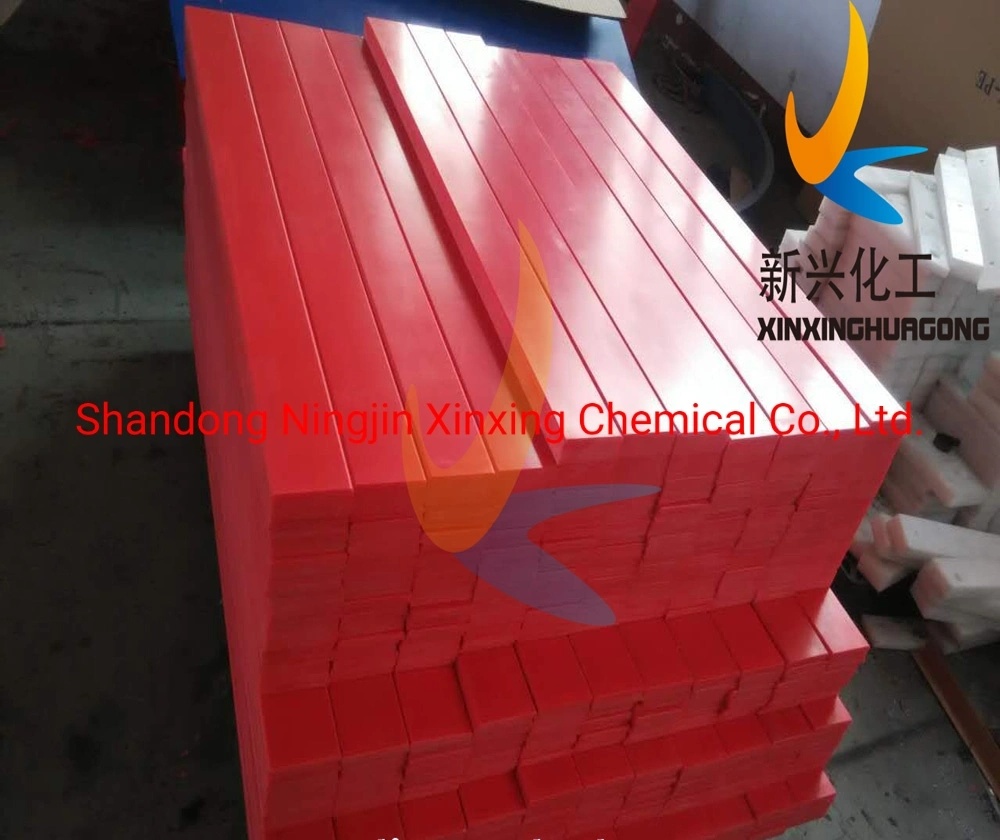

Various Rectangular, Square, Trapezoidal cross sections, "C" profile , special shapes, curves etc. are available suitable for all installations. Installation of these liners ensures prolonged working of dry chains in dusty atmosphere.

Properties

| Property: | Test Method (Standard) | Ticona GUI4152 | Ticona GUI4150,4120 | Unit |

| Molecular weight | 1.5million-4million | 1.5million-8million | ||

| Density | ISO 1183-1:2012/DIN53479 | 0.92-0.98 | 0.93-0.98 | g/cm³ |

| Compression strength | ISO 604:2002 | ≥30 | ≥32 | Mpa |

| Tensile strength | ISO527-2:2012 | ≥20 | ≥22 | Mpa |

| Elongation at break | ISO527-2:2012 | ≥280 | ≥300 | % |

| Dynamic Friction coefficient | ASTM D 1894/GB10006-88 | ≤0.20 | ≤0.18 | |

| Notched impact strength (Charpy) | ISO179-1:2010/GB/T 1043.1-2008 | ≥100 | ≥100 | kJ/m2 |

| Abrasion wear index | ES-X60210-2008 | ≤30 | ≤30 | mg |

| Vicat softing point | ISO306:2004 | ≥80 | ≥80 | °C |

| Hardness shore-D | ISO 868:2003 | 60-65 | 61-66 | D |

| Product name | HDPE strips |

| Features | Wear resistant Lightweight Durable Corrosion & impact resistant. Great weather resistance Easy to weld but difficult to bond. |

| Size | Max length:6000mm Max width:.2500mm Our company have 8 sets CNC machine to meet your any processing need. |

| Color | white,black,grey,red,blue,green,yellow,etc. |

Advantages

Self-lubricating.Good abrasion&wear resistance (15 times more resistant to abrasion than carbon steel).

Corrosion & impact resistant.

low temperature resistant.

Non-water absorption.

Easy to machine.

Excellent noise abatement.

Excellent impact strength.

Maintains key physical properties to -200° C.

Applications

These wear strips are mounted on the tracks over which the chain travels. Special antistatic grade of ultra high molecular weight polyethylene (UHMWPE) having antistatic property ensures its suitability for LPG installations, reducing chances of sparks / static current developed because of friction.

Various rectangular, square, trapezoidal cross sections, "C" profile , special shapes, curves etc are available suitable for all installations.

Installation of these liners ensures prolonged working of dry chains in dusty atmosphere.

Bottling / Conveying Machinery:

Wear Strips, Machined and Extruded Profiles as Guides, Star Wheels, Timing Screws, Dead Plates and Conveyor Curves. Ideal for use in Breweries, Canning Plants, etc.

Paper Industry:

Suction Box Tops, Forming Boards, Foil Blades, Doctor Blades and Sealing Strips.

Mining / Bulk Materials:

Chute Liners, Bin Liners, Truck Liners, Impact Slider Bars, Scraper Blades and Wear Plates.

Filter Industry :

Different kinds of filters like Drum Filters, Disc Filters, Belt Filters, etc.

Cold Rolling Industry :

Roll Pads, Roll Racks, Saddle Blocks, Roll Drives & Guide Boards.

Chemical Industry :

Spray Nozzles, Flanges, Impellers, Pump Casings, Filter Plates and Frames, Wear Parts for Belt Filters, etc.

About Shandong Ningjin Xinxing Chemical Co.,Ltd.

With the excellent experience of many years in manufacturing engineering plastics, Xinxing was established in 1989. Now, it becomes the largest and most professional manufacturer of Engineer plastics such as UHMWPE Sheets, ground protection mats, crane outrigger pads, UHMWPE fender pads, wear-resisting liners, HDPE Sheets and parts, PP sheets and parts and other engineer plastics.

Our factory covers an area of 36000 square meters which has 7 big workshops for different products and application. Xinxing is the only manufacturer that produces both extruded and pressed plastic products in China and represents the most advanced productive forces and highest quality.

Our products are widely exported to many countries all over the world such as Indonesia, Malaysia, Korea, Japan, Russia, Germany, India, England, Italy, South America, Canada, Chile, etc.

Our management creed is "Quality first, Customer first, Keeping improving". We are willing to establish a wide and continuous cooperation with enterprises home and abroad. We sincerely hope to establish business relations with you.

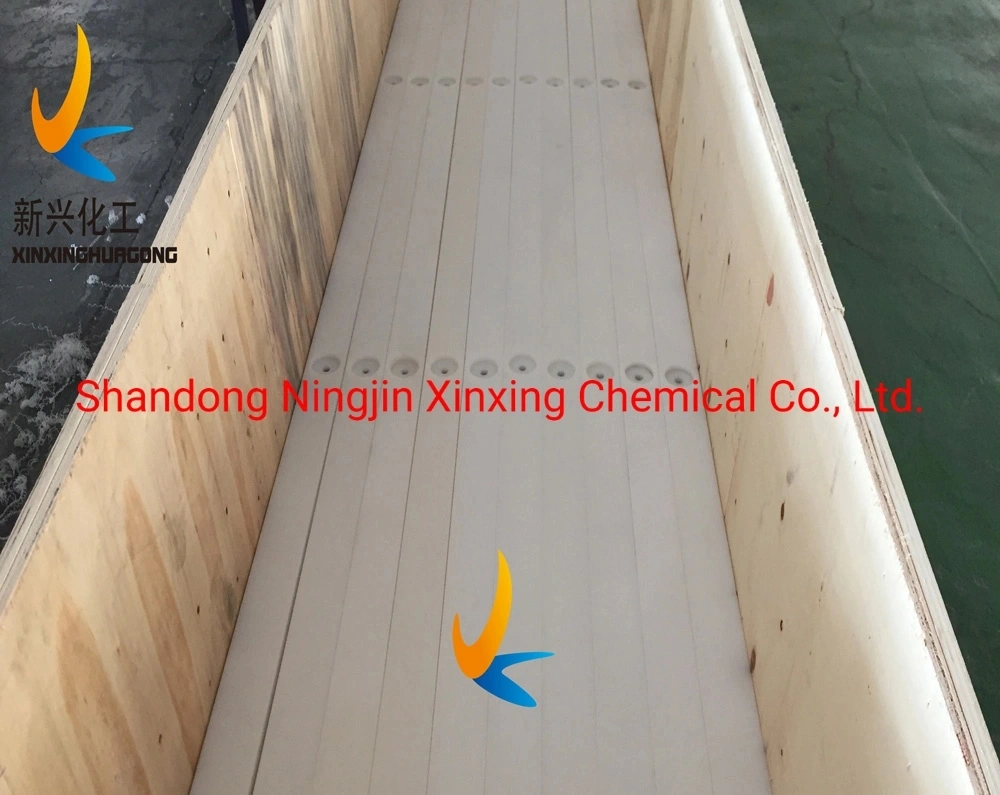

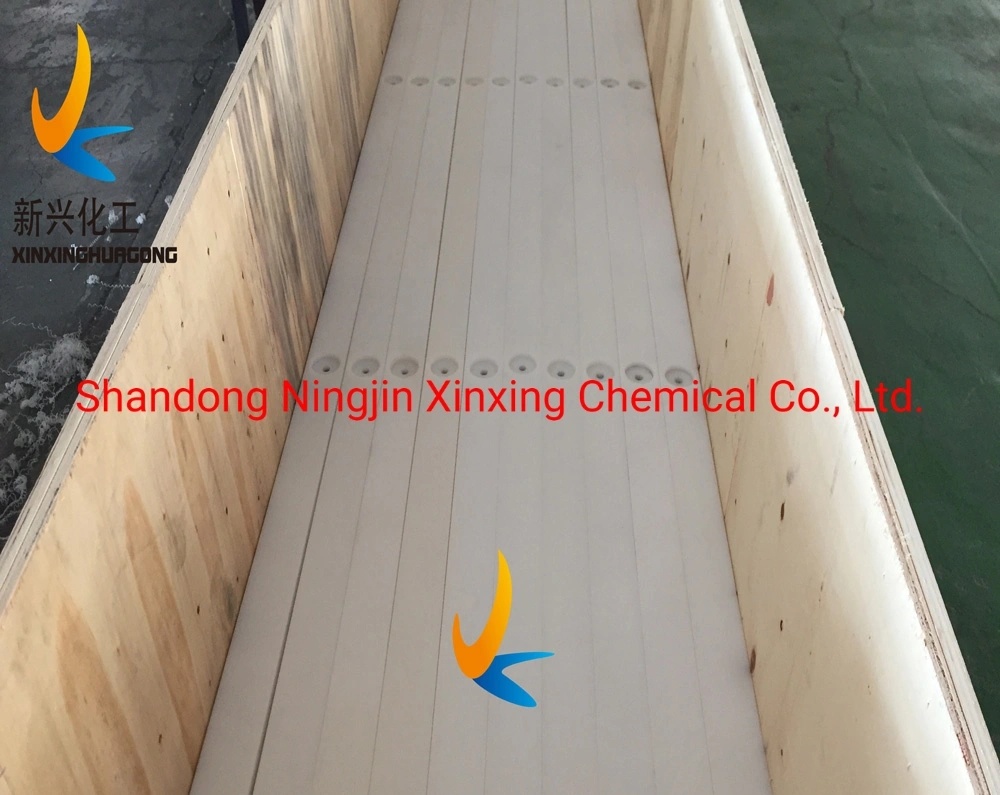

Product Packing

| Packing | Plastic Film, Pallet, Wooden Box, Carton, etc. |

| Shipping | International Express (DHL, UPS, FEDEX, EMS, etc.), Ocean Transport, Air Transport |